Manufacturers have been adopting physical technologies such as robotics and automated machine tools for many decades and have recently started to focus on additive manufacturing.

But many manufacturers are not aware of the power of data, the benefits that can be gained

from advanced data analytics, AI & Machine Learning or how to implement IoT platforms to leverage their key data assets.

Digital transformation relies heavily on data, as it cannot be delivered without it. So, it is important that manufacturers have a clear data strategy defined that will allow them to collect, integrate and utilise not only their internal data but external sources of insight and data.

According to the McKinsey Global Institute, the total annual potential of AI & ML – the value that can be created within industries – came to over $3.5 trillion across 19 industries and nine business functions for AI alone and over $9.5 trillion for AI and analytical techniques. Artificial Intelligence (AI) and Machine Learning (ML) powered technologies are playing a vital role in accelerating manufacturers capabilities in these areas and helping manufacturers achieve their goals to improve operational productivity, capture market share and remain globally competitive.

It is important for manufacturers and industrial leaders to first understand and what AI & ML are, why data and IoT is important for them, explore the value of AI applications in the market, and the benefits of adopting AI & ML inside and outside of the factory.

As AI & ML starts to be widely used across industries, adopting AI & ML inside & outside the factory will become a mandatory requirement for businesses to remain competitive and participate in sector and global supply chains.

So, what is AI and Machine Learning

Today the use of data and analysing it has become a huge subject with lots of terms such as Data Analysis and AI used commonly in everyday life.

Many definitions of machine learning float around. Machine learning is an application of artificial intelligence, that includes algorithms that parses the data, learn from the data, and then apply what they have learned to make informed decisions.

There are hundreds of examples of machine learning; a music streaming service, for instance, uses ML to make a decision about which new song or artist to recommend to a listener. Machine learning algorithms associate the listeners’ preferences with other listeners who have similar musical tastes. This technique is used in many services that offer an automatic recommendation.

The picture below gives you a representation of how AI, ML, Regression Models and Statistics, interact with each other and the amount of data required at for each step.

Importance of data in manufacturing

Data is at the heart of digital manufacturing, and as we have seen, it is fundamental for the implementation of AI & ML.

Manufacturers have always used data from designs and drawings translated into manufacturing jobs sheets and processes, or data from monitoring of production efficiency through time and motion study. The use of data in manufacturing is not new. However, with the advent of digital technologies, AI and ML, the collection and use of data has taken on new importance.

Data from inside and outside the factory now has real value and without its collection, storage and use, manufacturers cannot remain competitive or effectively interface with customers and suppliers. As a result, manufacturers are putting AI & ML at the centre of their digitalisation strategy and as reported in a survey by The AI Journal, in the wake of the crisis, close to three-quarters of business leaders (72%) feel positive about the role that AI will play in the future.

This is because they have learnt that AI & ML can be used to identify production and labour trends, spot changes in customers behaviour and demand, rectify maintenance and quality issues, minimise operational downtime, and reduce business risks. Many manufacturers already have access to large volumes of data.

The question they ask themselves is how they get value and ROI from data. AI and ML is the solution.

Read more about the importance of data in manufacturing here

AI Inside the Factory

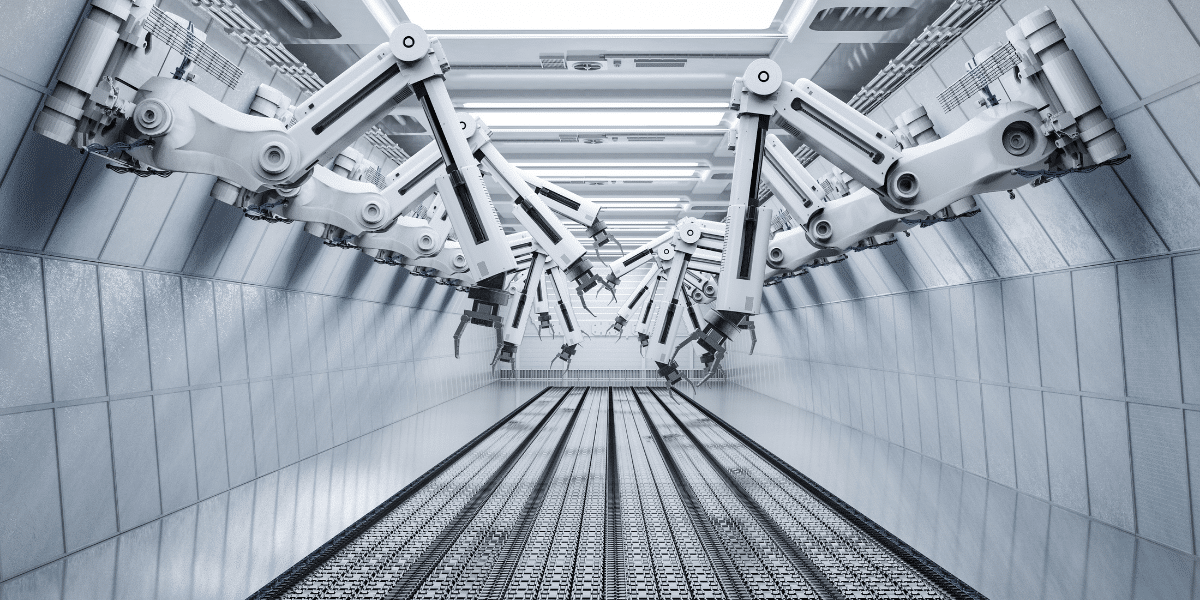

Inside the factory, digital technologies now allow you to create flexible and intelligent manufacturing processes, not reliant on humans, that can rapidly adapt to changes and allow bespoke products to be made at scale. The principles of Industry 4.0.

The Internet of Things (IoT) is a key asset in data collection and provides a key information platform from which AI & ML can be applied. It connects the physical world, both inside and outside the factory, to the digital world through sensors, edge and cloud computing.

AI and ML can then, through analytics, deliver insight, predict the future and instigate real-time change often actuated through an IoT platform and factory enterprise systems. It is important that manufacturers have a strategy and investments in place to build the ML/AI & IoT into their factories.

AI outside the factory

Outside of the factory, a typical supply chain involves many sub players, logistical interfaces, and geographical locations. The supply chain is depicted here as a linear flow but generally, they are three-dimensional complex networks.

If at any time, especially if the supply chain is lean, there is a failure in any one node in the supply network, many other parts can fail.

Synchronising demand and supply are key to avoiding the supply chain whiplash that has been experienced because of COVID.

AI and ML has a key role to play in the supply chain where the technology can be used to predict future risks and behaviours so that risks can be mitigated, and asset and product utilisation maximised.

Industrialising AI: How to Scale Intelligent Systems

We recognise that when organisations approach machine learning problems, they can historically encounter:

- Long and manual development process requiring skilled resource and time for ingestion, cleaning, modelling and deployment

- Large engineering overhead to build machine learning pipelines and ML-Ops infrastructure

- High cost of data transfer and compute for training and inference, as well as

- Complex regulatory and data privacy considerations in an increasingly fragmented and distributed data landscape.

Manufacturers need to access to their insights quickly and need to utilise automated pipelines to enable the use of this technology. We undertake a modular approach to development and use pre-packaged solutions to solve these challenges.